Products

Design considerations

- Dual electric motor architecture is more economical than one electric motor and a mechanical differential

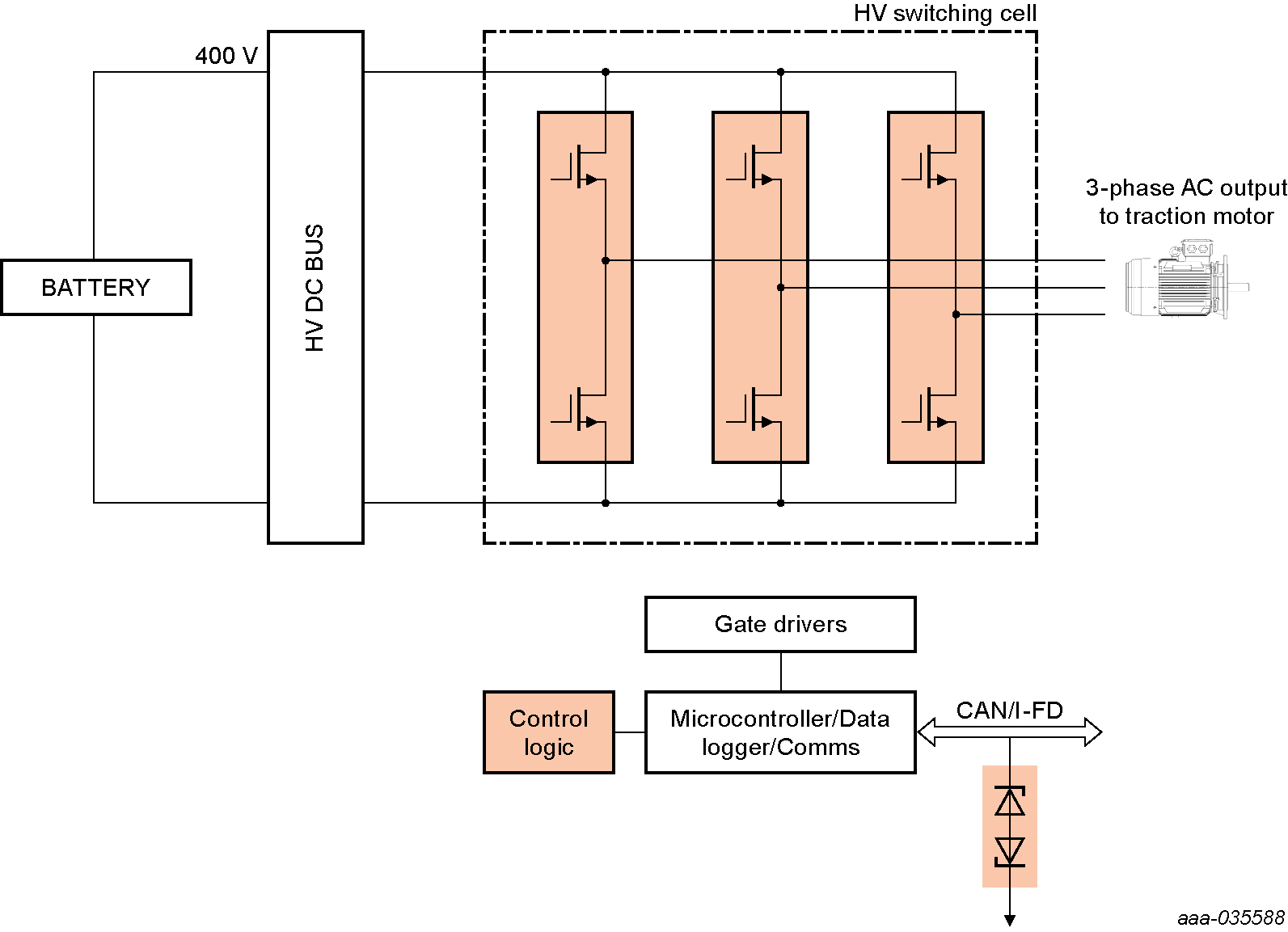

- In premium BEVs trend is to have separate inverters – one for each axle or one for each electric motor

- To maximise range, inverters need to be extremely efficient yet at the same time be as small as possible, often with multiple dies per switch (4 – 8) and multiple switches per inverter cell

- Using GaN FETs eliminates the need for a separate body diode in the inverter switches.

MOSFET and GaN FET Handbook

Drawing on over 20 years’ of experience, the MOSFET and GaN FET Application Handbook: A Power Design Engineer’s Guide brings together a comprehensive set of learning and reference materials relating to the use of MOSFETs and GaN FETs in real world systems.

Let us help you with product and design questions

Contact our technical support desk for your technical questions.