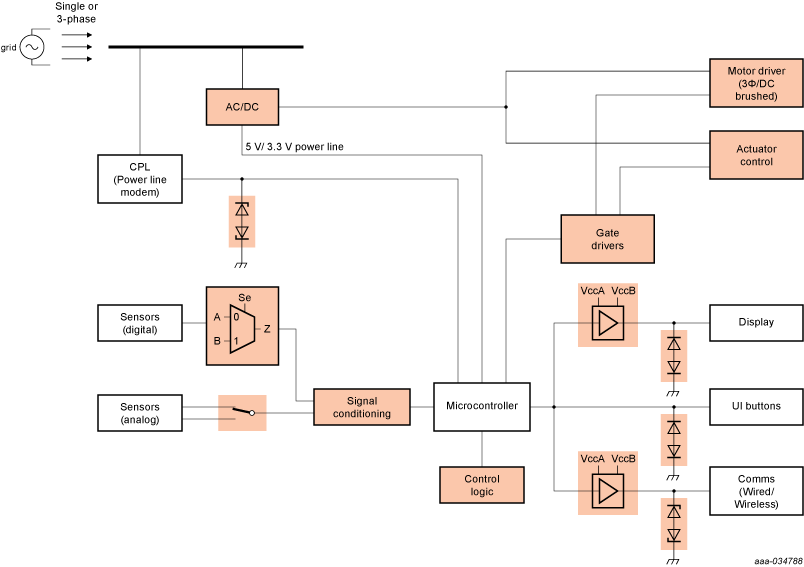

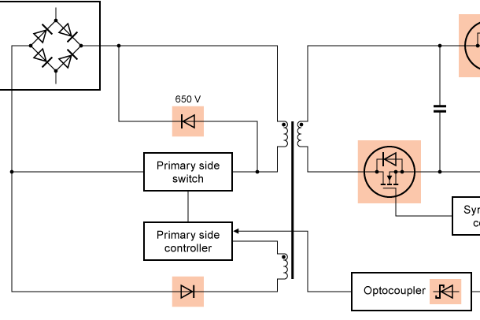

Products - AC-to-DC (PFC)

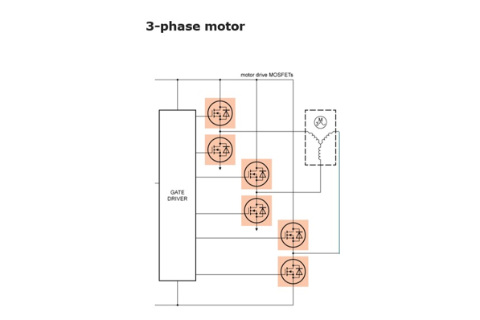

Products - Motor control

Products - DC-to-DC conversion

Products - Control Panel/Display/Comm

Design considerations

- In many factory automation applications thermal performance is critical and Nexperia's packaging options considerably lower thermal resistance

- Lower switch losses further improve thermal behaviour

- Reliable clip-bonding package technology for ensuring high anti stall robustness for motor drives

- Given the environment and applications transient voltages and electrostatic discharges can occur more often, requiring proven ESD protection for MMI / HMI and displays protection

- LFPAK and CFP allow a high-efficiency motor drive and DC/DC converter solutions while reducing costs (less heating to dissipate, smaller inductance and capacitor)

A deep understanding of factory automation

Building smart factory automation solutions requires key industry insights. Just as Nexperia's equipment and automation partner ITEC has benefited from understading semiconductor industry requirements, Nexperia also has had an intimate view on the requirements of factory automation.

Let us help you with product and design questions

Contact our technical support desk for your technical questions.