Sustainable volume assembly and test

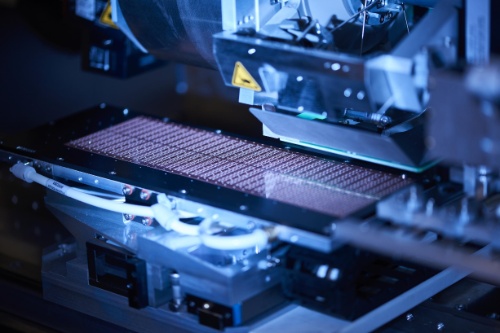

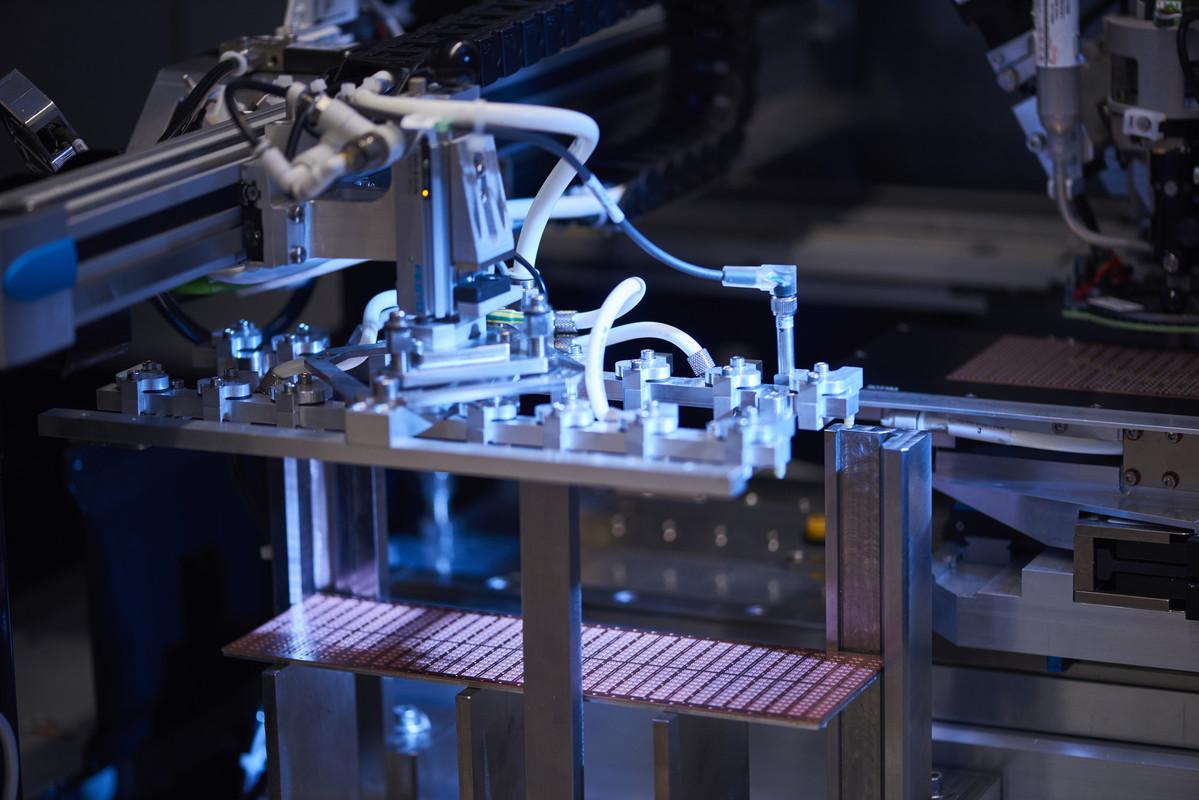

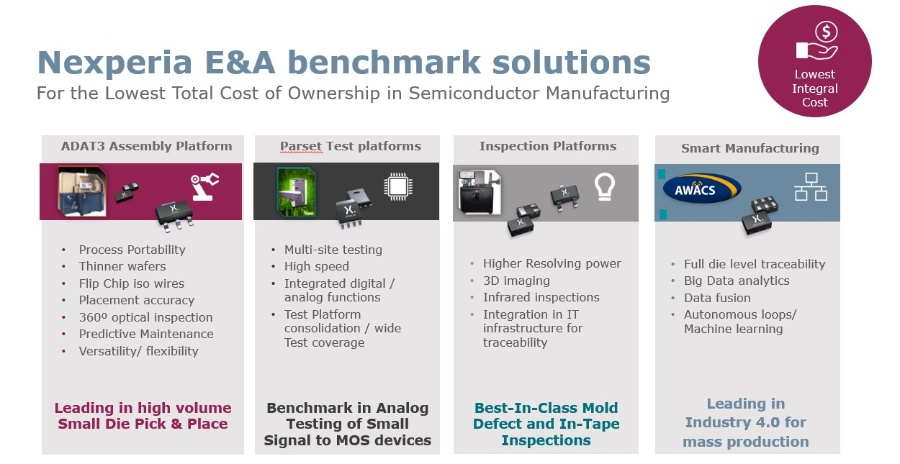

To truly deliver the efficiencies needed to assemble and test high-volume, high-quality semiconductors, ITEC draws on both technical expertise and manufacturing insights. Technical expertise delivers the advanced mechatronic systems, accurate test electronics, inspection algorithms and smart manufacturing big data handling our systems provide to customers. However, ensuring the highest productivity, throughput and quality at the lowest total cost of ownership requires a deep insight into the day-to-day challenges of manufacturing. Insights that ITEC has with 30 plus years as Nexperia’s (Philips / NXP) equipment and automation partner.

Pushing boundaries

But it doesn’t stop there. Ever since the introduction of the Breakthrough in Manufacturing (BIM) concept, ITEC is committed to incorporating the latest technologies and process expertise into tailored solutions. To enable our customers to excel in quality, productivity, and sustainability with the lowest total cost of ownership. Whether that is for standard discrete devices in the smallest packages and the latest dedicated high-power packages for wide bandgap (WBG) semiconductors, or new package materials and processes demanded by advanced RFID labels and LED displays. Ensuring the best commercial options are available for proven, high-quality, sustainable volume assembly and test operations.