- Block diagram

- Design considerations

- Design resources

- Product listing

- Videos

- Support

Block diagram

AC/DC converter

Power management

Sensors interface

Communications interface

Recommended products (3)

Signal conditioning

Gate driver

Recommended products (1)

Human-Machine interface

Recommended products (1)

Motor control

Recommended products (5)

Related evalutaion boards (1)

Select a component

To view more information about the Nexperia components used in this application, please select a component above or click on a component (highlighted in blue) in the block diagram.

Design considerations

- As cobots interact in shared space with humans, there cannot be any high power / live currents or elevated temperatures and ensure fail-safe mechanisms.

- BLDC motor is typically used - precise movement and positioning and torque sensing required.

- Designs are moving from a centralised architecture where all electronics are located in a cabinet to a decentralised architecture where each axis includes a controller

- Need for custom PCB design to sit in the joint alongside the motor, also increase need for small footprints with large power density

Design resources

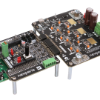

Evaluation boards

.png)

Product listing

AC/DC converter

Power management

Sensors interface

Communications interface

Signal conditioning

Gate driver

Human-Machine interface

Motor driver evaluation kit: quick start

Join Stein as he walks you through setup, wiring, and key features of this modular, open-source platform designed for BLDC motor control. Open-source firmware and design files are available under MITx licenses via Nexperia.com and GitHub, so you can customise every detail to suit your application.

Motor driver evaluation kit: detailed set-up

Explore what’s inside Nexperia’s fully open-source motor driver evaluation kit – designed to make your testing process more efficient. Join Aanas as he unboxes the kit, walks through its modular design, shows how quickly it sets up (just a USB-C charger), and demonstrates key features like current sensing, fault detection, and hall effect options.

.png)